Products:

- HSMDS Steam Showers for wet end

- HSMDS Steam Showers for calender applications

- Steam Control Systems related to steam showers

- HSMD-AquaJenty re-wetting Systems for CD moisture control

- HSMDS Steam Showers for special applications such as curl control, suppercalender, etc.

Are your Devronizer D5A-Actuators

giving you problems? Have a look at this actuator replacement opportunity.

(click below)

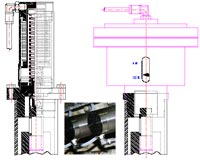

HSMDS Steam Shower Systems

Highly developed solutions and systems for delicate applications.

Individual and compact designs for versatile installations including sliding-out systems.

New developments for your specific machine environments.

Features and Benefits:

- Highly compact and individual design

- High volume preheat at diffuser (no dripping + higher range of controls)

- Not sensitive to pollution (runnability increase)

- Diffuser zones not drained (higher range of controls, no dripping)

- No constant zone (higher range of controls)

- Expertise in steam system engineering (excellent support by HUJ)

- Supply pressure vessel certification (absolute must now a days)

- High quality actuator technology

- Feed back signalling for set point supervision

- Not sensitive to diffuser adjustments (no runnability problems)

- High experience in case of steam spillage problems (fast solutions)

- No risk for pick-up felt destruction

- Excellent access for maintenance

- Saturated steam temperature at inlet without dripping (much higher performance due to better condensing) All competitors have to run superheated to prevent dripping.

- Robust

design : All

connections outside machine

- pneumatic quick disconnect outside machine

- highly simple maintenance of actuators

- all metallurgy in ASIA 316ti

- all retraction components in ASIA 316ti